SimSlosh

The Ultimate Fluid/Structure Interaction Simulation Tool

SimSlosh is an advanced software tool designed to simulate fluid/structure interaction, specifically addressing the challenges posed by sloshing in liquid containers. Employing a sophisticated coupling technique, SimSlosh separately models dynamic motion and fluid sloshing within the container.

What does SimSlosh do?

SimSlosh is your go-to solution for simulating fluid/structure interaction, providing detailed insights into the dynamic forces and torques applied to container walls due to sloshing.

Versatile Liquid Sloshing Simulation

Investigate liquid sloshing inside stationary and moving containers, such as offshore structures, road tankers, and automobile fuel tanks.

Complete 3-D Visualization

Delivers a comprehensive 3-D image of liquid waves inside the container, along with a detailed representation of all forces applied to the structures.

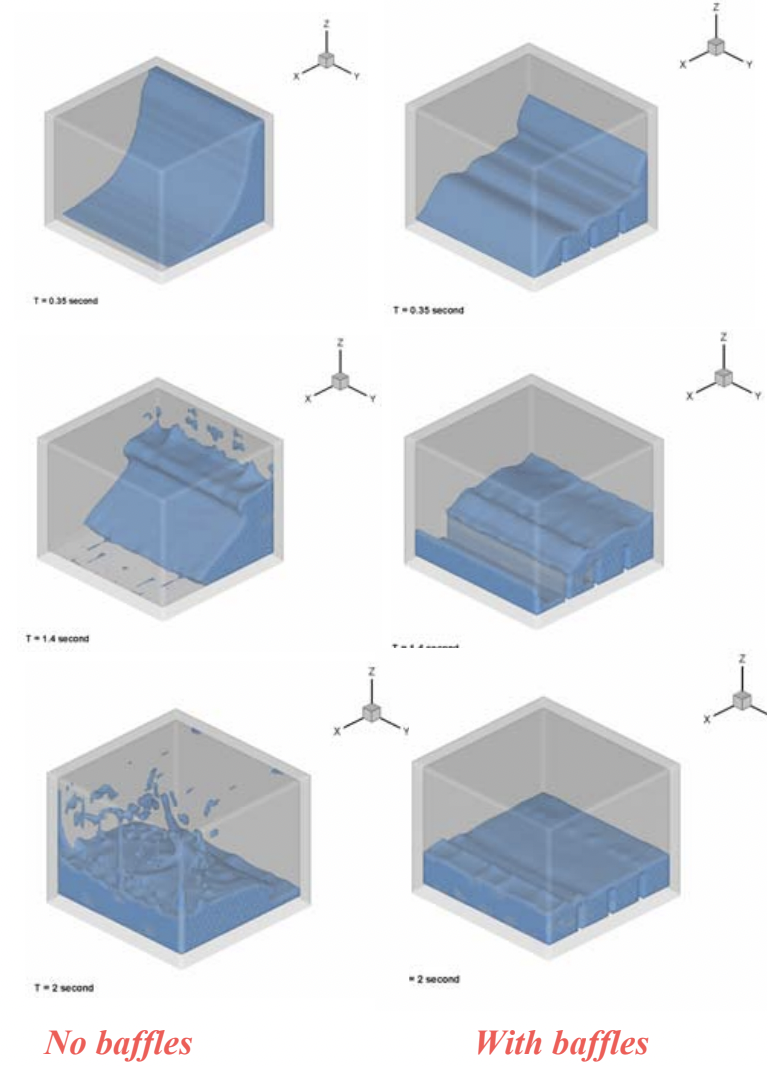

Baffle Design Analysis

Evaluate the effectiveness of various baffle designs to reduce sloshing effects and enhance container stability.

Control System Design

Simulate sloshing conditions to design more effective control systems, optimizing container performance.

Benefits

SimSlosh goes beyond the basics and offers a plethora of benefits:

Shape and Condition Flexibility

Simulate liquid sloshing inside containers with any complicated shape and under various conditions, providing a versatile solution for diverse applications.

Free Surface Flow Algorithm

SimSlosh utilizes a free surface flow algorithm, offering solutions in a moving system of reference for accurate and realistic simulations.

Dynamic Module for Real Road Conditions

Simulate real road conditions using a dynamic module that can be coupled to the liquid module, ensuring simulations align with practical scenarios

Eliminate "Clinking" Noises

Analyze and eliminate "clinking" noises produced in vehicle fuel tanks due to sloshing, enhancing the overall performance and user experience.

Time and Cost Savings

Save time and costs associated with prototyping and experimentation in the design or application of moving containers.